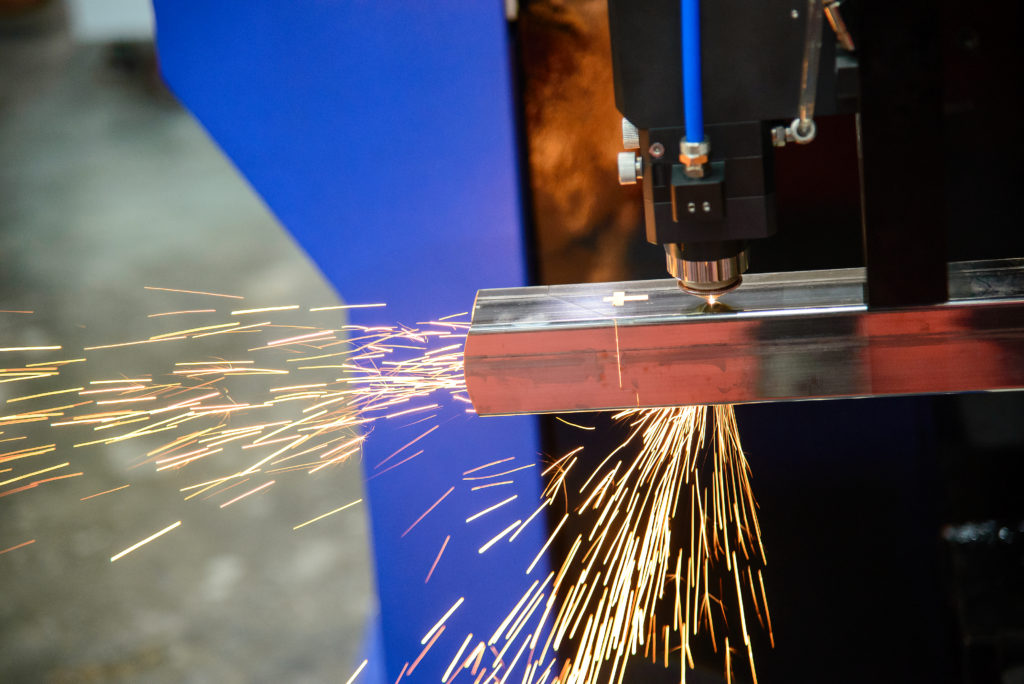

The process of tube laser cutting

Whether you’re looking for custom shapes or sizes, Ti-Tek guarantee a high level of precision and control with tube laser cutting. We recently invested in a state-of-the-art laser cutting machine to meet the growing demand for tube laser cutting and to replace outdated cutting tools and technology.

Let us walk you through the process of placing an order and explain how our fibre tube laser cutting machine works:

Step 1 – Enquiry

The process starts with an initial enquiry. Whether you provide a quick sketch of your design ideas or upload a detailed PDF file, we can help you to realise the best design and will be more than happy to discuss your requirements in further detail.

Our new laser metal cutting machine uses the latest technology and guarantees quick turnaround times for projects of all scales.

Step 2 – Quote

When we understand exactly what it is you’re looking to achieve, we can create a plan of action. By generating a plan, we not only ensure minimum waste but can provide a clear breakdown of the cost.

At Ti-Tek, we are always upfront about the fees for our tube laser cutting services and aim to provide a cost-efficient solution for all customers – saving you money on machinery, rental space and operators.

Step 3 – Design

Cutting metal into quality components takes time and accuracy – and is second nature to our skilled CAD engineers.

Our engineers complement our tube laser cutter and determine the best cutting sequence, maximise efficiency and reduce wastage.

Step 4 – Cutting

Our laser metal cutting machine operators need to know your requirements so we can provide the correct material, appropriate cutting program, parameters, and nozzle. We’ll also need to know:

- material sheet size

- grade

- batch number

- timescales

The laser head scans the edge of the metal sheet to ensure proper alignment – preventing over or under cutting. The fibre tube laser cutting machine will cut the metal effectively, working quickly and to tight timescales.

Step 5 – Delivery

As titanium suppliers, we make sure that all laser cut metals are delivered efficiently, meeting the demand of OEM’s (Original Equipment Manufacturers). Once we have cut metals to shape and size, we deliver them to a location of choice, making sure they arrive quickly and in great condition.

Contact Ti-Tek

If you need to know more about our tube laser cutting machine, the team at Ti-Tek is always on hand to help and will gladly guide and advise you. Find out more about our laser cutting machine and services today by calling us on 0121 382 4121 or email info@titek.co.uk.