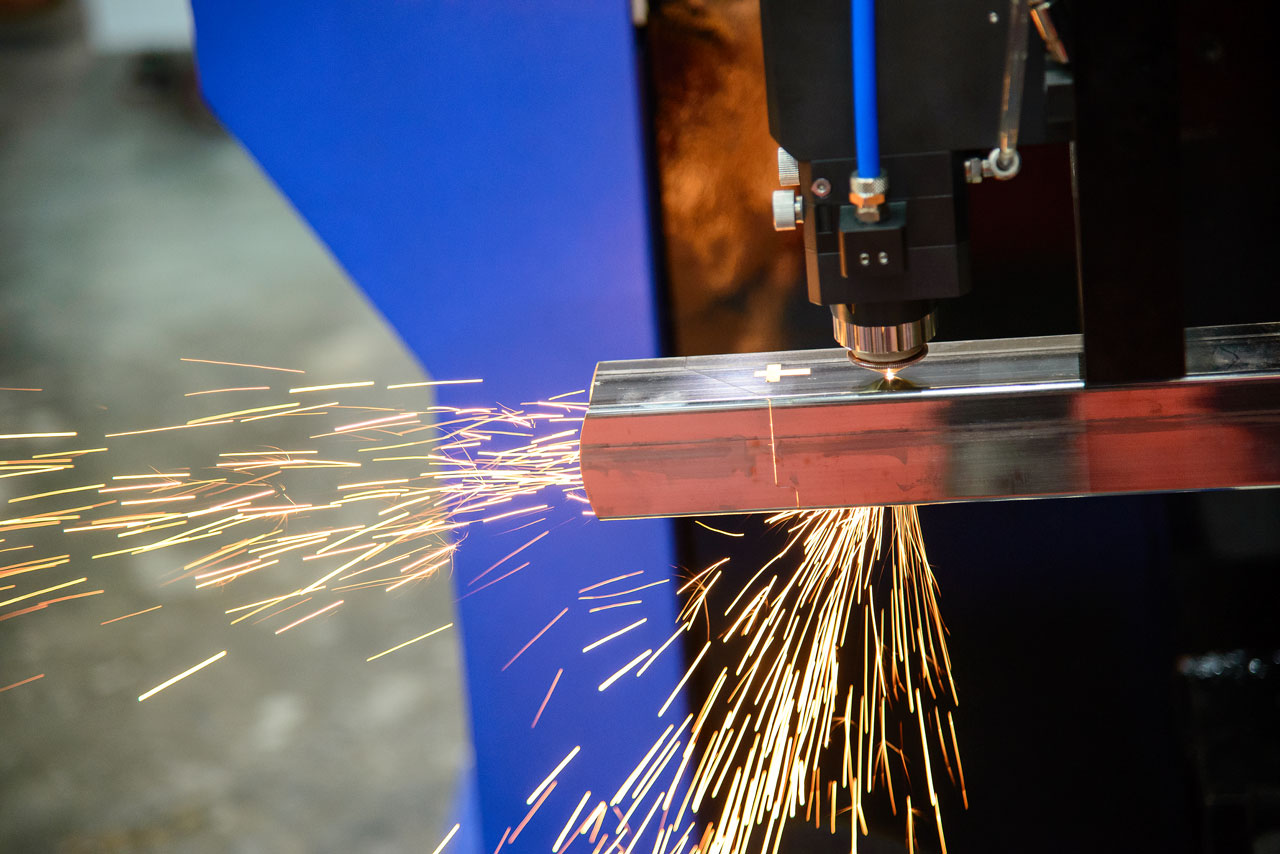

If you’re looking for precision cut titanium, you’ve come to the right place. Here at Ti-Tek, we’ve invested in a £120k fibre tube laser cutting machine to guarantee a clean, accurate cut every time.

Using our tube laser cutting machine, we cut titanium to a specific size to meet requirements and supply it to the Original Equipment Manufacturer (OEM) allowing Audi, BMW, Aston Martin to produce quality products.

Benefits of tube laser cutting:

- Diversity

Here at Ti-Tek, we aim to provide a suitable solution for all clients. Whether you’re looking for custom shapes or sizes, we guarantee a high degree of control and precision, providing you with exactly what you need.

Our fibre tube laser cutting machine ensures niche roles are filled, allowing us to make:

- vertical cuts

- angle cuts

- slots

- etchings

- bevel cuts

…and many more.

- Improve efficiency

Instead of using a blade that leaves metal shavings and imperfections, the tube laser cutter creates a virtually perfect edge and collects the waste materials – ensuring they’re kept away from the tube being cut.

What’s more, our laser cutting machine can cut a tube-shaped object directly, eliminating the need to cut a flat piece of metal and then put it through a roller.

- Strong tube ends

As well as smoother cuts, the tube laser cutting machine applies no mechanical force. A Computer Numerically Controlled (CNC) punch is an alternative to laser cutting and requires a physical force to break through the material. Our tube laser cutter ensures that tubes are strong at the point of the cut, reducing the stress that’s placed on the surrounding material which could cause it to weaken.

Contact Ti-Tek

If you need to know more about our laser metal cutting machine, and how we can assist you with laser tube cutting, please get in touch. Our team is always on hand to help and will be more than happy to share their expertise. Call us on 0121 382 4121 or email info@titek.co.uk today.